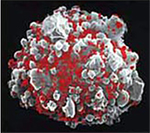

Consisting of polymer nanospheres using proprietary and patented PNS technology for HIV, influenza and anthrax vaccines

Vaccine Adjuvants

Vaccination is the most cost-effective tool for the control and prevention of infectious diseases. However, multiple inoculations are often required to achieve desirable protection even with potent antigens.

Vaccination is the most cost-effective tool for the control and prevention of infectious diseases. However, multiple inoculations are often required to achieve desirable protection even with potent antigens.

In order to increase the therapeutic efficiency of such vaccines, adjuvants are used with vaccines to augment the immune response. There are several types of adjuvants with different modes of action. Adjuvants form a depot of antigen at the site of inoculation with slow release of antigens. Adjuvants can improve the performance of vaccines by targeting the antigen to antigen-presenting cells, eliciting specific cytokines that direct Th1 or Th2 immune responses. Most of the adjuvants increase the production of specific antibodies. Adjuvants that enhance cell-mediated immunity for vaccines against bioterrorist agents are desirable since many of these agents are intracellular pathogens.

Several vaccines are under development and testing for HIV, influenza and bioterrorism agents. Most of these vaccines are recombinant or purified subunit vaccines. These subunit vaccines are being developed because they are safer than whole-cell vaccines. However, these subunit vaccines often result in weaker immune responses. The use of adjuvants capable of enhancing and directing the immune response to subunit vaccines is a critical component of rational vaccine design.

Current Vaccine Adjuvant Technology

Presently in the United States, aluminum salt- or gel-based adjuvants are the predominant adjuvants used in licensed vaccines. In 2009, the FDA approved, for the first time, a vaccine that includes monophosphoryl lipid A (MPL) as an adjuvant in addition to the aluminum hydroxide adjuvant (FDA newsletter, July 7, 2011).

However, concerns have been raised recently about long-term toxicity from aluminum with potential for autoimmunity and long-term brain inflammation with the associated neurological complications (Tomljenovic and Shaw, 2011).

Biodegradable Polymer Microspheres as Novel Vaccine Adjuvants

Microspheres, comprised of biodegradable hydrophobic copolymers, appear to have an adjuvant effect on microencapsulated anthrax rPA, possibly caused by its controlled release and/or immune stimulation of the dendritic cells by the copolymer (Flick-Smith et al., 2002).

While highly promising, the hydrophobic microspheres are manufactured from organic solvents. There are certain problems associated with the use of conventional organic phase solvents in polymer microencapsulation.

Manufacturing Problems with Current Polymer Microspheres Technologies

- Vaccine antigens are exposed to potentially denaturing organic solvents, such as methylene chloride and ethyl acetate, which can adversely affect the integrity of the final product.

- Large scale processing utilizes large quantities of organic solvents.

- Current processes are very time-consuming, costly and inefficient.

- Residual toxic organic solvents in the final product can cause adverse reactions in recipients.

- Compliance with organic solvent limits established by regulatory authorities in the United States and Europe could be a challenge.

- There are environmental waste disposal and potential contamination issues.

- Stability of protein antigens in the body at ambient temperature for long periods is problematic.

- Immunogenicity of microencapsulated vaccine antigens to induce the production of protective or neutralizing antibodies is an issue.

Aphios’ Vaccine Adjuvant Technology

To circumvent these problems, Aphios has developed a novel process for making biodegradable polymer nanospheres (PNS) that avoids the use of organic solvents (US Patents, Castor, 2006, 2010 and 2011).

To circumvent these problems, Aphios has developed a novel process for making biodegradable polymer nanospheres (PNS) that avoids the use of organic solvents (US Patents, Castor, 2006, 2010 and 2011).

- This technology encompasses nanotechnology.

- The process is enabled by the use of supercritical, critical or near-critical fluids with or without polar cosolvents such as ethanol [referred to as SuperFluids™ or SFS].

- Biodegradable biopolymers are dissolved in SuperFluids™ and mixed with the subunit vaccine in aqueous solution or as a slurry of nanoparticles.

- The mixture is decompressed into an aqueous solution, liquid nitrogen or an empty vessel (spray dryer).

- As a result of decompression, polymer nanospheres are formed, encapsulating the subunit vaccine.

Advantages and Benefits

- The use of SuperFluids™, instead of organic solvents such as ethyl acetate and methylene chloride, reduces exposure of encapsulated therapeutic proteins and vaccine antigens to potentially denaturing organic solvents.

- The use of SuperFluids™ also eliminates the need to remove any residual organic solvents in the final drug product.

- SuperFluids™ biodegradable polymer nanospheres have the potential for the scaled-up production of nanospheres vaccine formulations protective against anthrax.

- Use of SFS greatly reduces the processing time and the cost associated with the preparation of biodegradable polymer microspheres containing therapeutic products while maintaining the uniformity and integrity of the vaccine antigens.

- In addition to reduction or elimination of organic solvent usage, utilizing supercritical fluids for microspheres may impart advantages of product sterility; there are a number of reports demonstrating the microbicidal and virucidal effects of supercritical fluids (Fischer et al., 1991; Lin et al., 1992; Castor et al., 1995, 1999, 2002).